Please contact us for more information!

Linde has developed leading technologies to optimise reheating furnaces. REBOX® is not a ”one size fits all” solution but a portfolio of approaches tailored to different furnace and application requirements. REBOX® solutions can be incorporated into new and existing furnaces without increasing the existing footprint. They are compatible with all conventional fuels and most types of furnaces, from large pushers and walking beams through rotary hearths, roller hearths to various batch furnaces.

Linde also developed an effective way to optimize vessel preheating processes for the metal industry. Our OXYGON® preheating system is available in two versions for different vessel sizes and different levels of flexibility.

When you want to improve the performance with minimum changes to your existing operation, we recommend increasing the oxygen content using high velocity lances.

>>> More about REBOX® HLL

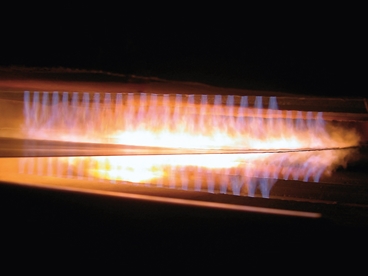

When you want to maximise the benefits of oxygen and are willing to replace the combustion system, we have developed flameless oxyfuel.

>>> More about REBOX® flameless oxyfuel

When you are looking for rapid pre-heating, degreasing as well as pre-oxidation of steel strips in continuous galvanising and annealing lines.

>>> More about REBOX® DFI

With its powerful OXYGON® solution, we offer an effective means of optimising vessel preheating processes for the metal industry. This technology moves beyond conventional burner designs to harness highly efficient flameless oxyfuel combustion and thus reduce energy consumption by your ladle preheater.

>>> More about OXYGON®

Would you like to have more information?

Contact our experts